|

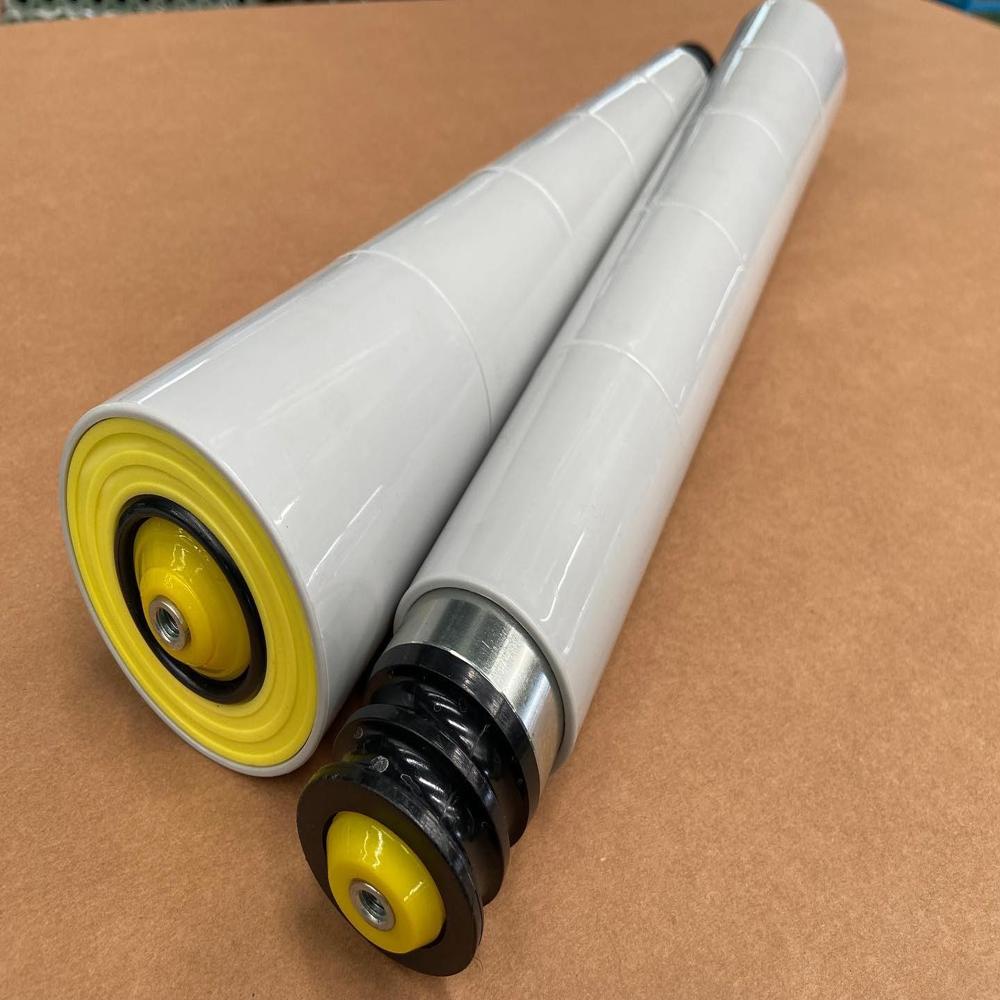

Tail Pulley

Tail Pulley Specification

- Thickness

- 8 mm to 20 mm shell thickness Millimeter (mm)

- Features

- Precision machined, dynamically balanced

- Surface Finish

- Painted / Powder Coated

- Belt Type

- Flat or Trough

- Material

- Mild Steel or Stainless Steel

- Type

- Tail Pulley

- Structure

- Heavy Duty Steel

- Belt Conveyor

- Compatible

- Roller Conveyor

- Not Compatible

- Resistant Feature

- Corrosion Resistant

- Load Capacity

- Up to 5000 kg Kilograms (kg)

- Speed

- Custom as per belt system Km/s

- Usage & Applications

- Used at the tail end of belt conveyor systems

- Diameter

- 150 mm to 1000 mm

- Operating Temperature

- -10C to +80C

- Standards

- IS:8531 compliant

- Shaft Material

- EN8/EN9 steel

- Installation Position

- Tail end of conveyor

- Customization

- Available as per requirement

- Mounting

- External bearing housing

- Lagging Option

- Plain/Rubber/Patterned lagging available

- Bearing Type

- Sealed heavy-duty bearings

- Length

- Up to 2200 mm

- End Disc Material

- Mild Steel

About Tail Pulley

Key Applications and Outstanding Usage Advantages

The Tail Pulley excels at the tail end of belt conveyor systems, ensuring efficient and reliable material handling in industries such as mining, cement, steel, and power plants. Its adaptable structure suits both flat and trough belt types, with heavy-duty features providing long-lasting, trouble-free performance. The advantage lies in its robust construction, dynamic balance, corrosion resistance, and a range of lagging optionsall contributing to reduced downtime and optimal system operation.

Payment Terms, Domestic Market, and Shipping Details

Tail Pulleys are offered at the lowest possible price without compromising quality. Serving the entire Indian domestic market, we ensure shipped goods arrive securely and on time, supported by partnered transport services. Packaging details are tailored as per client requirements to guarantee safe delivery. We accept multiple convenient payment modes, facilitating hassle-free transactions. Take advantage of our reliable shipping and support services to ensure seamless procurement and installation for your operations.

FAQs of Tail Pulley:

Q: How do I choose the right Tail Pulley size for my conveyor system?

A: Select the diameter, length, and shaft material based on your belt conveyors width, load requirements (up to 5000 kg), and site specifications. Our experts can assist with customization for optimal fit.Q: What are the main benefits of using this heavy-duty Tail Pulley?

A: The main advantages include corrosion resistance, dynamically balanced operation, superior strength, compatibility with different belt types, and reduced maintenance, leading to efficient and long-lasting performance.Q: Where can Tail Pulleys be installed within conveyor systems?

A: Tail Pulleys are specifically installed at the tail end of belt conveyor systems and are not compatible with roller conveyors.Q: What lagging options are available and why are they valuable?

A: Customers can choose from plain, rubber, or patterned lagging. These enhance belt grip, reduce slippage, and offer abrasion resistance, making them a valuable addition for various demanding applications.Q: How is the product shipped and packaged to ensure safety?

A: Tail Pulleys are securely packaged according to client needs, using reliable transport services to ensure shipped goods arrive intact. Special care is taken for safe handling during transit.Q: What customization is possible for this Tail Pulley?

A: We offer extensive customization in terms of dimensions, shaft materials, lagging types, surface finish, and speed to precisely suit your application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Flexible Conveyors

Thickness : 3 Meter

Resistant Feature : Oil Resistant

Structure : Roller

Surface Finish : Crome

Usage & Applications : Food

Load Capacity : 100 Kilograms (kg)

Rubber Belt

Thickness : 5 mm to 20 mm

Resistant Feature : Other, Heat Resistant, Wear Resistant, Oil Resistant

Structure : Other, Belt Conveyor

Surface Finish : Smooth

Usage & Applications : Material Handling, Industrial Conveyors, Mining, Packaging

Load Capacity : Up to 2000 kg/m

Carrying Idlers

Thickness : As per specification (commonly 3 mm to 8 mm shell thickness)

Resistant Feature : Other, Corrosion resistant, Abrasion resistant

Structure : Other, Three roller troughed or flat

Surface Finish : Powder coated or Painted

Usage & Applications : Bulk material handling, mining, cement, power plants, steel plants, etc.

Load Capacity : 50 to 2000 kg as per design

Head Pulley

Thickness : 12 mm to 30 mm

Resistant Feature : Other, Corrosion Resistant, Wear Resistant

Structure : Other, Heavy Duty Cylindrical Steel

Surface Finish : Polished / Painted

Usage & Applications : Used in belt conveyor systems as a drive or discharge pulley in industries such as mining, cement, power plants, etc.

Load Capacity : Up to 2500 kg

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry