|

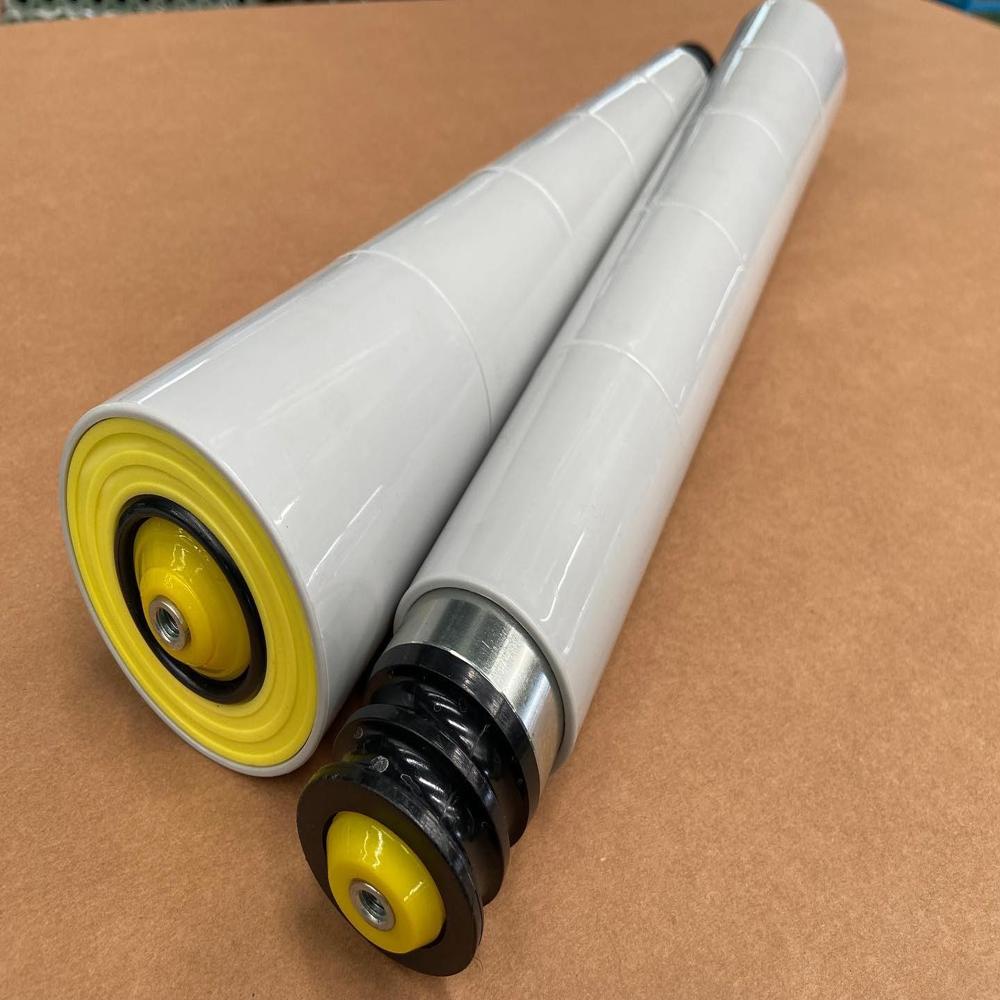

Magnet Pulley

Magnet Pulley Specification

- Features

- Easy installation, Low maintenance, Durable design, Continuous operation

- Power Source

- Electric

- Surface Finish

- Polished or Powder Coated

- Thickness

- Approx. 8 mm to 25 mm

- Belt Type

- Rubber, PVC, or as specified

- Material

- Stainless Steel / Mild Steel body with strong permanent magnets

- Type

- Magnet Pulley

- Structure

- Drum Pulley with magnetic core

- Belt Conveyor

- Compatible

- Roller Conveyor

- Not Compatible

- Resistant Feature

- Corrosion Resistant

- Load Capacity

- Up to 500 kg/hr (varies with model size)

- Voltage

- 220V / 380V

- Power

- 2 HP (Customizable as per requirement)

- Speed

- Adjustable as per application

- Usage & Applications

- For separation of ferrous contaminants from bulk materials on conveyor belts; mining, recycling, cement, grain processing industries

- Manufacturing Standard

- ISO/CE certified fabrication

- Mounting Type

- Flange/Bearing Mounted

- Magnetic Field Strength

- Up to 3500 Gauss

- Ambient Operating Temperature

- -10°C to +80°C

- Finishing Options

- Mirror finish, Matte finish

- Pulley Diameter Range

- 150 mm to 600 mm

- Customization

- Size and specifications customizable based on application

- Maintenance

- Minimal; periodic inspection recommended

- Noise Level

- Low (less than 70 dB)

- Magnet Type

- High-intensity permanent magnet

- Pulley Length Range

- 200 mm to 1600 mm

About Magnet Pulley

Special Features & Industrial Uses of the Magnet Pulley

The Magnet Pulley is engineered for first-class performance and reliability, boasting continuous operation with low maintenance requirements. Its superior corrosion resistance and high-intensity permanent magnetic core efficiently separate ferrous contaminants from bulk materials. Widely used in plants within mining, recycling, cement, and grain processing industries, its robust drum pulley structure ensures valiant durability in challenging environments. Easy to install and compatible with various belt types, this pulley is designed for seamless integration into existing conveyor systems.

Magnet Pulley Samples, Export Markets & Payment Terms

Magnet Pulley samples are available upon request at a favorable sale price or on quotation basis to facilitate customer satisfaction. Our main export markets include Africa, the Middle East, Asia, and domestic markets throughout India. We offer flexible payment terms, including T/T, LC, and other customer-preferred methods, to streamline procurement processes. As a leading exporter, distributor, and service provider, our exceptional offerings ensure smooth transactions and reliable after-sales support for international and domestic clientele.

FAQs of Magnet Pulley:

Q: How does the Magnet Pulley separate ferrous contaminants during operation?

A: The Magnet Pulley uses a high-intensity permanent magnetic core that attracts and holds ferrous contaminants as bulk materials pass over the conveyor, ensuring effective separation and cleaner final products.Q: What are the main applications of the Magnet Pulley in industrial plants?

A: It is primarily used in industries such as mining, recycling, cement, and grain processing to remove ferrous impurities from bulk materials, thereby protecting downstream machinery and improving product quality.Q: When should the Magnet Pulley be maintained or inspected?

A: Periodic inspections are recommended, although the design requires minimal maintenance. Ensuring routine checks will optimize its performance and prolong its service life.Q: Where can I purchase or reserve the Magnet Pulley in India?

A: You can secure this product directly from our official channels as a manufacturer, supplier, and distributor. Samples and customization details are available upon request.Q: What are the benefits of using a high-intensity permanent Magnet Pulley?

A: Benefits include first-class magnetic separation efficiency, phenomenal durability, easy installation, low maintenance, and suitability for continuous operation in demanding industrial environments.Q: How is the Magnet Pulley installed in an existing conveyor system?

A: The pulley comes with flange or bearing mounting options for easy integration into belt conveyor systems using rubber, PVC, or custom-specified belts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Tail Pulley

Surface Finish : Painted / Powder Coated

Thickness : 8 mm to 20 mm shell thickness Millimeter (mm)

Resistant Feature : Other, Corrosion Resistant

Material : Mild Steel or Stainless Steel

Load Capacity : Up to 5000 kg Kilograms (kg)

Usage & Applications : Used at the tail end of belt conveyor systems

Rubber Belt

Surface Finish : Smooth

Thickness : 5 mm to 20 mm

Resistant Feature : Other, Heat Resistant, Wear Resistant, Oil Resistant

Material : High Grade Rubber

Load Capacity : Up to 2000 kg/m

Usage & Applications : Material Handling, Industrial Conveyors, Mining, Packaging

Return Idlers

Surface Finish : Powder coated or painted

Thickness : Gauge standard: 36 mm

Resistant Feature : Other, Corrosion and abrasion resistant

Material : Mild steel or steel

Load Capacity : 100350 kg per idler

Usage & Applications : Used to support return side of conveyor belts in mining, material handling, aggregate, and construction industries

Shaft

Surface Finish : Polished

Thickness : Custom as per requirement

Resistant Feature : Other, Corrosion Resistant

Material : Highgrade Steel

Load Capacity : Up to 5000 kg (varies with application)

Usage & Applications : Machines, conveyors, automotive, industrial equipment

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry