|

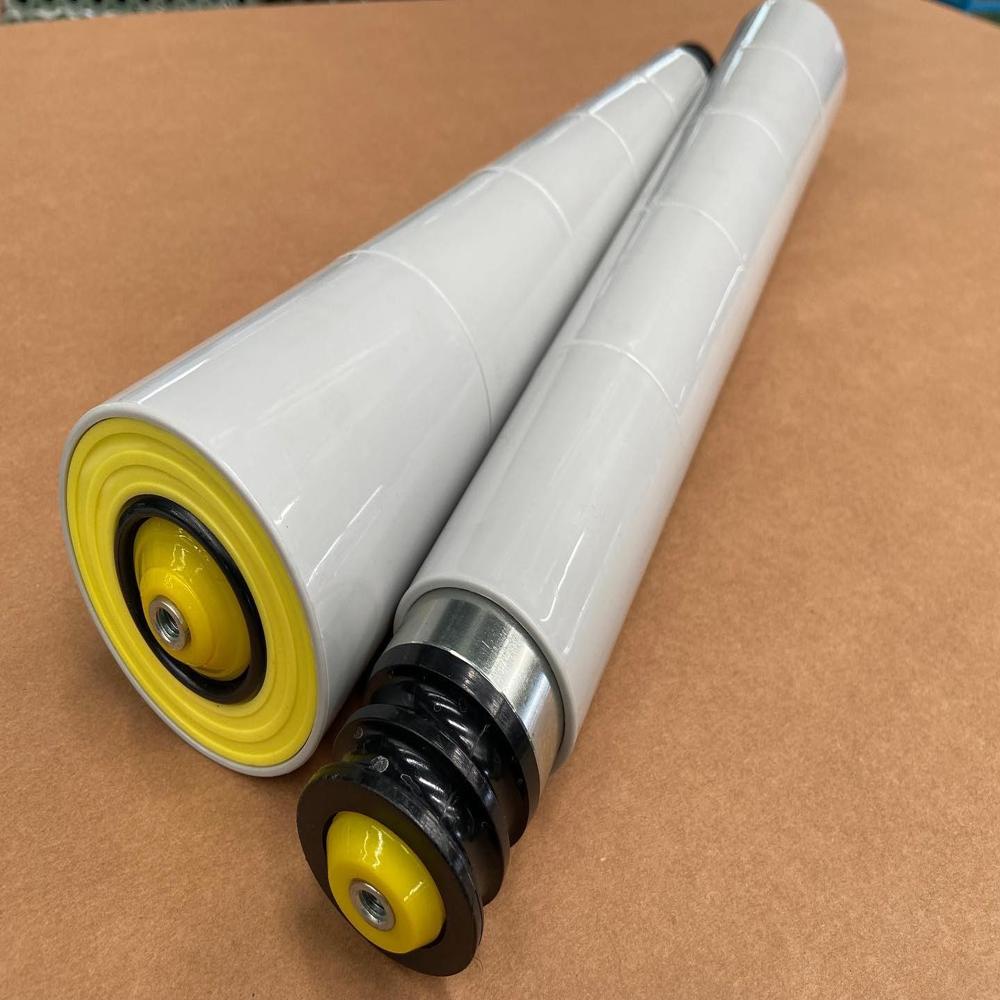

Cema Idlers

Cema Idlers Specification

- Surface Finish

- Powder coated or galvanized

- Thickness

- Shell thickness 3 mm 10 mm

- Belt Type

- Flat and Troughed Belt

- Features

- High precision, low rolling resistance, maintenance free

- Material

- Mild Steel, Stainless Steel, Polymer

- Type

- Carrying Idler, Return Idler, Impact Idler, Troughing Idler

- Structure

- Steel frame with sealed bearing housing

- Belt Conveyor

- Compatible

- Roller Conveyor

- Supported

- Resistant Feature

- Corrosion and abrasion resistant

- Load Capacity

- Up to 10,000 kg per idler

- Speed

- Compatible with belts up to 5 m/s

- Usage & Applications

- Used in bulk material handling systems for mining, cement, port, power and construction industries

- Mounting

- Bolt-on arrangement

- Noise Level

- Low noise operation, <70 dB

- Roller Diameter

- Available from 89 mm to 219 mm

- Working Temperature

- -20°C to +80°C

- Painting

- Epoxy coated (customizable)

- Custom Sizes

- Available on request

- Bearing Type

- Double sealed ball bearing

- Idler Angle

- Troughing angles from 20°, 35°, 45°

About Cema Idlers

Versatile Applications for All Industries

Cema Idlers are engineered for both general and specific uses, making them indispensable across a range of sectors, including mining, cement, power plants, ports, and construction. With their robust build, they handle bulk materials efficiently in conveyor systems and are suited for both flat and troughed belt types. Apart from typical industrial applications, they also excel in demanding environments where durability and reliability are critical for continuous, trouble-free material transport.

Secure Packaging, Samples, and Certifications Offered

Each Cema Idler is securely packaged to ensure damage-free delivery in both domestic and international markets. We offer samples upon request and can provide detailed quotations tailored to your projects requirements. Our products are certified for quality assurance, meeting industry standards for safety and performance. Leveraging our expertise as a manufacturer, supplier, distributor, and exporter, we ensure prompt service and complete documentation, enhancing your investment confidence.

FAQs of Cema Idlers:

Q: How do Cema Idlers improve conveyor reliability in bulk material handling?

A: Cema Idlers enhance reliability with high precision components, double sealed ball bearings, and corrosion-resistant construction, resulting in low rolling resistance and maintenance-free operation for long-lasting performance.Q: What are the available customization options for Cema Idlers?

A: Custom sizes, roller diameters, surface finishes (powder coated or galvanized), and painting specifications can be tailored to your requirements. Materials include mild steel, stainless steel, and polymer components.Q: When should I choose a specific idler type (carrying, return, impact, troughing)?

A: Select the idler type based on application needs: carrying for material support, return for belt reversal support, impact for shock absorption at loading points, and troughing for guiding bulk material flow on belts.Q: Where can I use these idlers besides mining and cement industries?

A: Cema Idlers are also suitable for ports, power plants, and construction projectsany facility requiring bulk material handling with conveyor or roller systems benefits from their robust performance.Q: What is the process for obtaining a sample or quotation for Cema Idlers?

A: You may request samples directly, and our team will provide a detailed quotation based on your projects requirements. Complete packaging and certification details will be included to support your decision-making process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Flexible Motorized Conveyors

Minimum Order Quantity : 1 Meter

Thickness : 2 Millimeter (mm)

Resistant Feature : Oil Resistant

Structure : Roller

Material : MS/SS

Load Capacity : 100 Kilograms (kg)

Tail Pulley

Minimum Order Quantity : 100 Pieces

Thickness : 8 mm to 20 mm shell thickness Millimeter (mm)

Resistant Feature : Other, Corrosion Resistant

Structure : Other, Heavy Duty Steel

Material : Mild Steel or Stainless Steel

Load Capacity : Up to 5000 kg Kilograms (kg)

HDPE Roller

Thickness : 4 mm to 8 mm

Resistant Feature : Other, Corrosion & Wear Resistant

Structure : Other, Cylindrical, Troughing or Flat

Material : HighDensity Polyethylene (HDPE)

Load Capacity : Up to 200 kg per roller

Self Aligning Return Idler

Thickness : 3 6 mm roller shell

Resistant Feature : Other, Corrosion and weather resistant

Structure : Other, Frame with roller(s)

Material : Mild Steel (MS), rubber lining optional

Load Capacity : Up to 300 kg per roller

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry