|

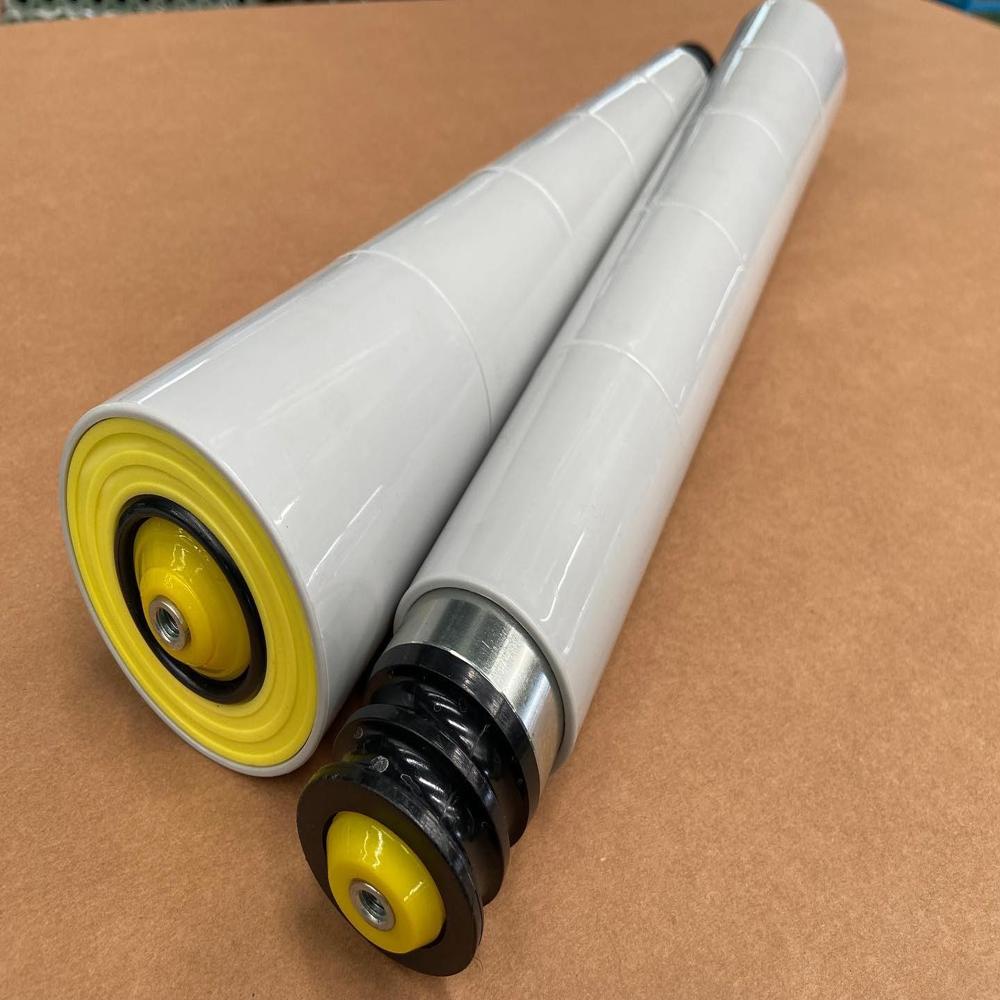

Head Pulley

Head Pulley Specification

- Power Source

- Mechanical

- Features

- Heavy-duty construction, Easy maintenance, Excellent grip, Long service life

- Surface Finish

- Polished / Painted

- Belt Type

- Flat & Chevron

- Thickness

- 12 mm to 30 mm

- Material

- Mild Steel (MS), Rubber Lagging Optional

- Type

- Head Pulley

- Structure

- Heavy Duty Cylindrical Steel

- Belt Conveyor

- Compatible

- Resistant Feature

- Corrosion Resistant, Wear Resistant

- Load Capacity

- Up to 2500 kg

- Speed

- Variable, as per application

- Usage & Applications

- Used in belt conveyor systems as a drive or discharge pulley in industries such as mining, cement, power plants, etc.

- Weight

- Depends on dimensions, up to 1800 kg

- Shaft Diameter

- 30 mm to 200 mm

- Customization

- Size & Lagging as per requirement

- Lagging Type

- Plain or Diamond Rubber Lagging

- Mounting

- Keyed Shaft

- Standards

- IS 8531, CEMA

- Finish

- Anti-rust Coating Available

- Operating Temperature

- -10°C to +80°C

- Pulley Diameter

- 200 mm to 1600 mm

About Head Pulley

Versatile Use and Industry Applications

Our Head Pulley is expertly used as a drive or discharge component in belt conveyor systems. Suitable for both flat and chevron belt types, it excels in environments requiring secure, heavy-duty operationsuch as mining sites, cement plants, material handling operations, and power generation facilities. Its robust cylindrical steel design ensures it adapts seamlessly to a variety of industrial setups, offering reliability for continuous, high-load usage.

Certifications, Payments, and Global Markets

Certified to IS 8531 and CEMA standards, our Head Pulley assures dependable quality and safety. We support flexible payment terms, including the option to submit a purchase order for a swift estimate and convenient drop-off or export. Our main export markets include India and several international regions. The product is trusted by distributors, exporters, importers, and service providers seeking robust, customizable solutions in competitive global sectors.

FAQs of Head Pulley:

Q: How can the Head Pulley be customized for specific conveyor systems?

A: The Head Pulley offers customization in diameter, shaft size, lagging type (plain or diamond), and finish. You can tailor these features to best fit your conveyor specifications and operating requirements.Q: What are the main benefits of using a rubber lagged Head Pulley?

A: A rubber-lagged Head Pulley provides excellent grip, reduces belt slippage, and enhances wear resistance, which extends the longevity of both pulley and conveyor belt.Q: When is an anti-rust coating recommended for the Head Pulley?

A: Anti-rust coating is highly recommended for installations in damp, corrosive, or outdoor environments to ensure long-lasting corrosion resistance and optimal performance.Q: Where can the Head Pulley be installed?

A: The Head Pulley is suitable for use in mining sites, cement factories, power plants, and any industry that operates heavy-duty belt conveyor systems.Q: What is the process for placing a purchase order and receiving an estimate?

A: Simply submit your requirements for size and lagging type via our instant checkout or contact us directly to receive an estimate. Upon confirmation, we proceed with manufacturing and arrange a convenient drop-off or shipping schedule.Q: What type of belt does this Head Pulley support?

A: It is compatible with both flat and chevron conveyor belts, making it versatile for various materials and handling needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Flexible Conveyors

Minimum Order Quantity : 1 Meter

Resistant Feature : Oil Resistant

Surface Finish : Crome

Type : Incline and Decline Conveyor

Material : MS/SS

Load Capacity : 100 Kilograms (kg)

Friction Roller

Resistant Feature : Other, High resistance to abrasion and corrosion

Surface Finish : Polished / Rubber coated

Type : Other, Friction Roller

Material : Mild steel or stainless steel with rubberized coating

Load Capacity : Up to 300 kg per roller

Tail Pulley

Minimum Order Quantity : 100 Pieces

Resistant Feature : Other, Corrosion Resistant

Surface Finish : Painted / Powder Coated

Type : Other, Tail Pulley

Material : Mild Steel or Stainless Steel

Load Capacity : Up to 5000 kg Kilograms (kg)

Impact Idlers

Resistant Feature : Other, Impact resistant, abrasion resistant

Surface Finish : Anticorrosive surface coating

Type : Other, Impact Idler

Material : Steel tube with highquality rubber rings

Load Capacity : Heavyduty, suitable for high impact zones at conveyor loading points

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry