|

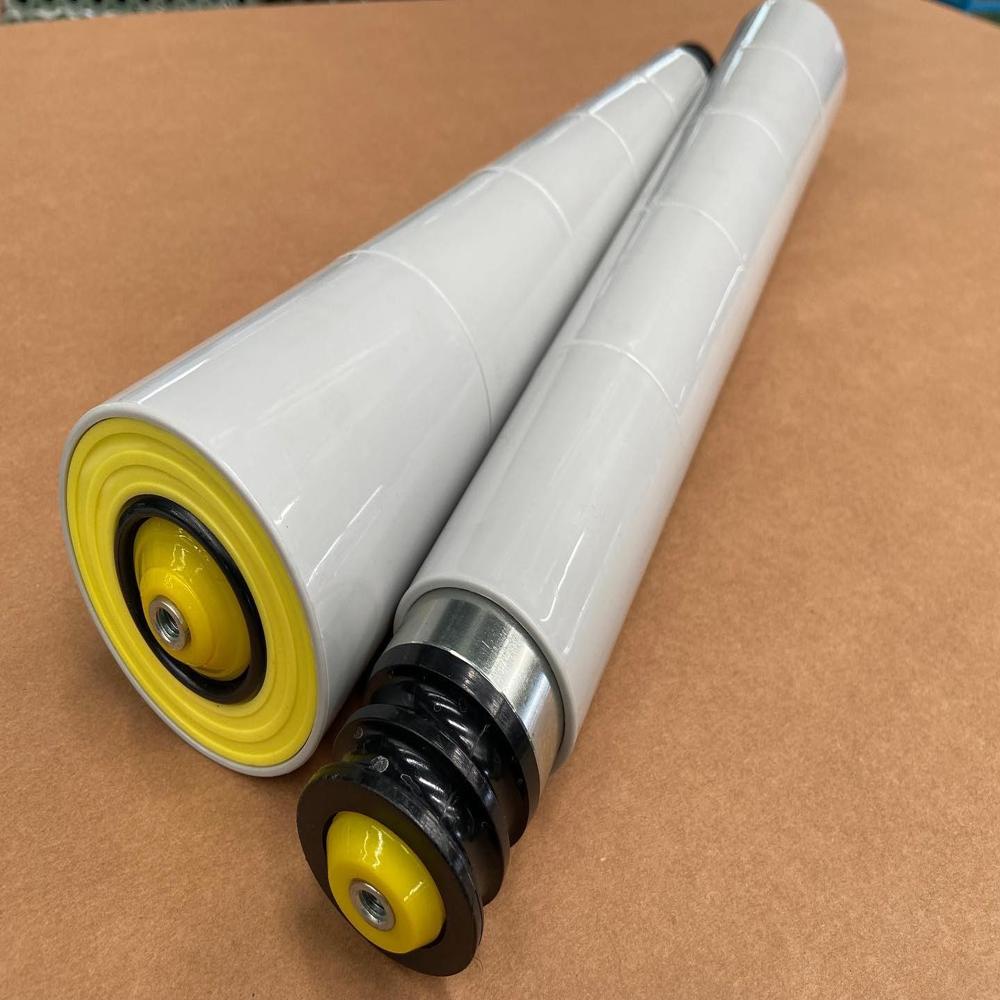

Self Aligning Return Idler

Self Aligning Return Idler Specification

- Thickness

- 3 - 6 mm roller shell

- Belt Type

- Flat belt supported

- Features

- Self-aligning action, heavy-duty design, easy installation, low maintenance

- Surface Finish

- Galvanized / Painted

- Power Source

- Mechanically driven by conveyor motion

- Material

- Mild Steel (MS), rubber lining optional

- Type

- Self Aligning Return Idler

- Structure

- Frame with roller(s)

- Belt Conveyor

- Compatible

- Roller Conveyor

- Return Idler Application

- Resistant Feature

- Corrosion and weather resistant

- Load Capacity

- Up to 300 kg per roller

- Speed

- Depends on conveyor system

- Usage & Applications

- Used for maintaining belt alignment and support return side of the conveyor belt in material handling systems

- Number of Rollers Per Set

- Single or twin roller set

- Mounting Type

- Standard through brackets/welded to frame

- Color Options

- Black, Blue, or Yellow

- Industry Usage

- Mining, Quarry, Power Plant, Cement, Steel, Fertilizer, Port handling systems

- Axle Type

- Fixed or loose

- Operating Temperature

- -30°C to +80°C

- Noise Level

- Low

- Bearing Type

- Sealed spherical/self-aligning bearings

- Roller Length

- Customized as per belt width (400 mm to 2200 mm)

- Roller Diameter

- 89 mm to 159 mm

- Suitable Belt Width

- 400 mm to 2200 mm

- Standards Followed

- IS 9295 / CEMA / ISO

About Self Aligning Return Idler

Versatile Usage and Application

The Self Aligning Return Idler is ideal for return side belt alignment in conveyor systems across demanding industries like mining, quarry, cement, power plants, steel mills, fertilizer production, and port handling. Its usage type includes both flat belt supported and return idler conveyor applications. Designed to accommodate a variety of mounting and axle options, this component seamlessly integrates with belt widths ranging from 400 mm to 2200 mm, ensuring reliable alignment and reduced maintenance downtime.

Export Market, Certification & Supply Reputation

Global valuation for our Self Aligning Return Idler remains impressive, with widespread acceptance in export markets including Asia, Africa, Europe, and the Middle East. A robust supply ability ensures quick fulfillment at prudent outlay, maximizing operational efficiency. Secure shipping guarantees product integrity during transit. Each idler complies with IS 9295, CEMA, and ISO standards, reinforcing our commitment to quality and safety through certified manufacturing processes.

FAQs of Self Aligning Return Idler:

Q: How does the self-aligning action of the Return Idler enhance belt conveyor performance?

A: The self-aligning feature automatically corrects belt misalignment during operation, minimizing downtime, reducing wear on the belt, and improving overall system reliability in material handling applications.Q: What industries benefit most from using this Self Aligning Return Idler?

A: Industries such as mining, cement, quarry, steel, fertilizer, power plants, and ports benefit from this idlers robust construction, easy installation, and low-maintenance design for heavy-duty material handling.Q: Where can these idlers be installed and what mounting options are available?

A: These idlers can be installed on belt conveyors of various sizes using standard brackets or by welding directly to the frame, suitable for both new and retrofit conveyor systems.Q: What certifications does the Self Aligning Return Idler meet?

A: This product meets IS 9295, CEMA, and ISO industry standards, ensuring superior quality, durability, and safety for global material handling applications.Q: What is the process for customizing the roller length to match specific belt widths?

A: Roller length is tailored based on customer specifications for belt widths between 400 mm and 2200 mm, ensuring optimal fit and performance for unique conveyor designs.Q: How does the sealed spherical bearing design contribute to low maintenance?

A: The sealed self-aligning bearings prevent ingress of contaminants and reduce the need for frequent lubrication, ensuring low noise and trouble-free operation even in harsh environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Flexible Motorized Conveyors

Minimum Order Quantity : 1 Meter

Load Capacity : 100 Kilograms (kg)

Resistant Feature : Oil Resistant

Structure : Roller

Thickness : 2 Millimeter (mm)

Material : MS/SS

Housing

Load Capacity : Upto 20 Tons

Resistant Feature : Other, Corrosion Resistant

Structure : Other, Mild Steel Frame

Thickness : 2 mm 10 mm

Material : Mild Steel (MS)

Tail Pulley

Minimum Order Quantity : 100 Pieces

Load Capacity : Up to 5000 kg Kilograms (kg)

Resistant Feature : Other, Corrosion Resistant

Structure : Other, Heavy Duty Steel

Thickness : 8 mm to 20 mm shell thickness Millimeter (mm)

Material : Mild Steel or Stainless Steel

Magnet Pulley

Load Capacity : Up to 500 kg/hr (varies with model size)

Resistant Feature : Other, Corrosion Resistant

Structure : Other, Drum Pulley with magnetic core

Thickness : Approx. 8 mm to 25 mm

Material : Stainless Steel / Mild Steel body with strong permanent magnets

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry