|

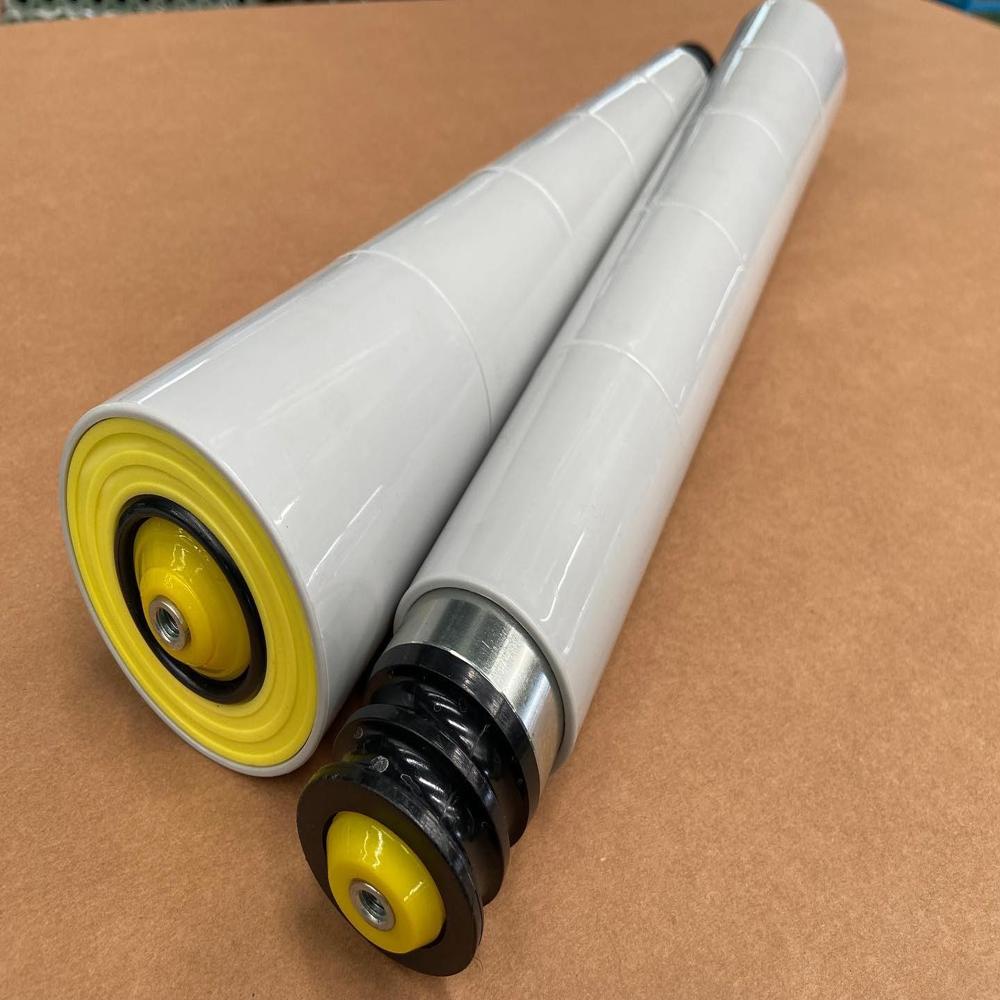

Self Aligning Carrying Idler

Self Aligning Carrying Idler Specification

- Belt Type

- Flat or Troughed Conveyor Belt

- Surface Finish

- Powder Coated / Painted / Galvanized

- Features

- Automatically aligns itself to correct belt misalignment, reduces edge damage, robust construction, maintenance free

- Power Source

- Not Required (Non-Powered)

- Thickness

- 3-5 mm (Roller Shell)

- Material

- Mild Steel / Stainless Steel / Rubber Coated (Optional)

- Type

- Self Aligning Carrying Idler

- Structure

- Heavy Duty Steel Frame with Rollers

- Belt Conveyor

- Compatible

- Roller Conveyor

- Compatible

- Vertical Conveyor

- Not Suitable

- Resistant Feature

- Corrosion Resistant, Dust Resistant

- Load Capacity

- Standard and customized options available, typically up to 3 tons per idler

- Voltage

- Not Required (Mechanical Only)

- Power

- Not Applicable (Manual/Gravity Driven)

- Speed

- Up to 3.15 m/s (Depending on belt application)

- Usage & Applications

- Used for bulk material handling, cement, mining, quarry, thermal power, and other conveyor systems

- Noise Level

- Low

- Roller Length

- As per belt width specification

- No. of Rollers / Set

- 2 or 3, depending on application

- Application Environment

- Suitable for outdoor and indoor installations

- Sealing System

- Sealed bearings for dust and moisture protection

- Roller Diameter

- 89 mm, 102 mm, 114 mm or as per customer requirement

- Customization

- Available as per client specification

- Installation

- Bolted to conveyor frame

- Operating Temperature Range

- -20°C to +80°C

About Self Aligning Carrying Idler

Stellar Performance Across Multiple Surfaces and Applications

The Self Aligning Carrying Idler is purpose built for use on flat or troughed conveyor belts in both indoor and outdoor settings. It excels in application areas like mining, bulk material handling, cement, quarry, and thermal power plants. Competitive advantages include its automatic belt alignment feature, minimization of edge damage, and maintenance-free operation, providing reliability and peace of mind for a wide range of industrial sectors.

Packaging, Supply, and Export Market Overview

Our Self Aligning Carrying Idler is packaged securely for safe goods transport, ensuring products reach their destination in stellar condition. We maintain a robust supply ability to meet both standard and custom order estimates efficiently. With a strong footprint in the global export market, we serve clients as a manufacturer, exporter, and supplier, delivering quality and value to countries around the world from India.

FAQs of Self Aligning Carrying Idler:

Q: How does the Self Aligning Carrying Idler help prevent belt misalignment?

A: The Self Aligning Carrying Idler automatically adjusts its position to correct belt misalignment, reducing edge damage and enhancing operational efficiency in conveyor systems.Q: What applications are suitable for this idler?

A: It is ideal for use in cement plants, mining operations, quarries, thermal power stations, and other bulk material handling industries, both indoors and outdoors.Q: Where can this product be installed?

A: This idler can be bolted directly onto the conveyor frame of compatible belt or roller conveyors, making it suitable for a wide range of material handling systems except vertical conveyors.Q: What competitive advantages does your idler offer?

A: Our idler features robust construction, corrosion and dust resistance, low noise, automatic alignment, and maintenance-free operation, offering outstanding longevity and operational savings.Q: When is customization available for this idler?

A: Customization is available upon request to match specific roller diameters, lengths, load capacities, and surface finishes to meet unique operational requirements.Q: How is the product packaged and delivered to export markets?

A: Each unit is packaged to ensure secure goods transport, supporting safe delivery to both domestic and international export markets with prompt estimate-based supply capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Magnet Pulley

Load Capacity : Up to 500 kg/hr (varies with model size)

Surface Finish : Polished or Powder Coated

Type : Other, Magnet Pulley

Roller Conveyor : Other, Not Compatible

Usage & Applications : For separation of ferrous contaminants from bulk materials on conveyor belts; mining, recycling, cement, grain processing industries

Features : Easy installation, Low maintenance, Durable design, Continuous operation

Tail Pulley

Load Capacity : Up to 5000 kg Kilograms (kg)

Surface Finish : Painted / Powder Coated

Type : Other, Tail Pulley

Roller Conveyor : Other, Not Compatible

Usage & Applications : Used at the tail end of belt conveyor systems

Features : Precision machined, dynamically balanced

Self Aligning Return Idler

Load Capacity : Up to 300 kg per roller

Surface Finish : Galvanized / Painted

Type : Other, Self Aligning Return Idler

Roller Conveyor : Other, Return Idler Application

Usage & Applications : Used for maintaining belt alignment and support return side of the conveyor belt in material handling systems

Features : Selfaligning action, heavyduty design, easy installation, low maintenance

Impact Idlers

Load Capacity : Heavyduty, suitable for high impact zones at conveyor loading points

Surface Finish : Anticorrosive surface coating

Type : Other, Impact Idler

Roller Conveyor : Other, Applicable

Usage & Applications : Bulk material handling, mining, cement plants, steel mills

Features : Absorbs impact from falling material, prolongs belt life, reduces maintenance

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry