|

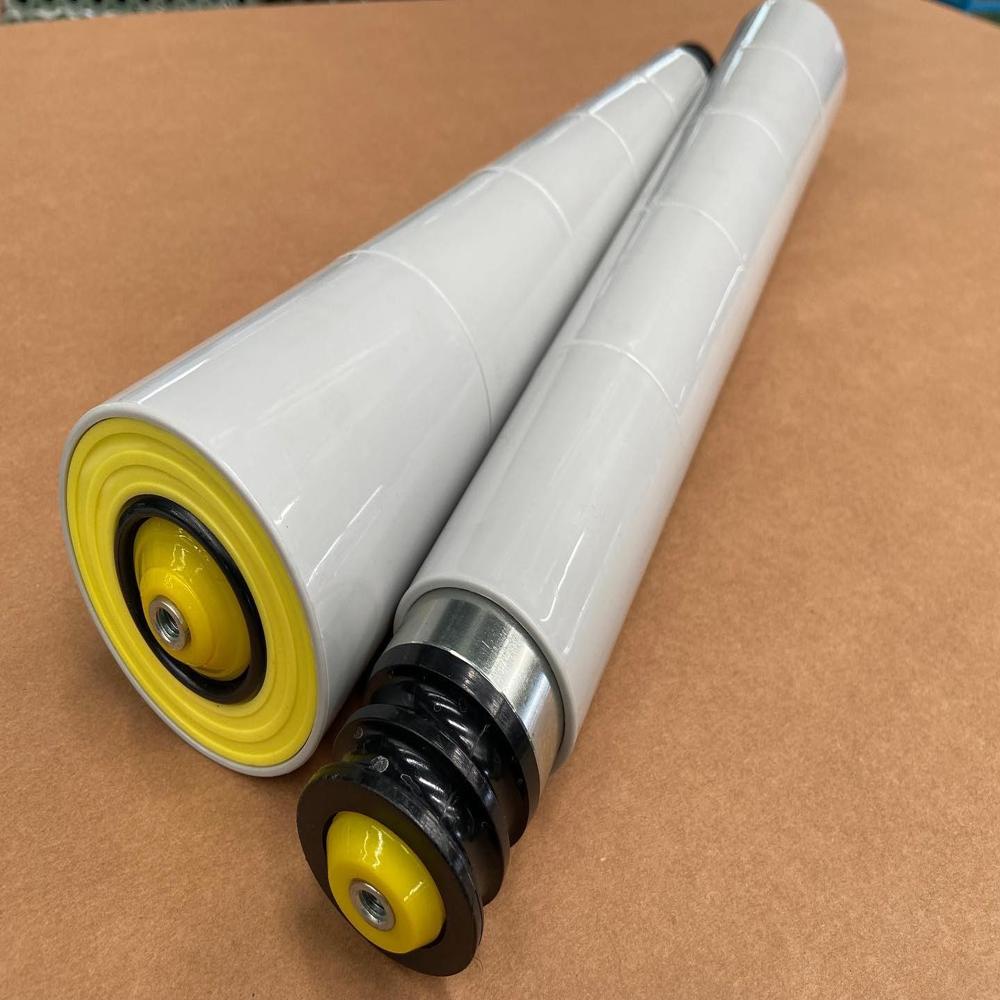

Friction Roller

Friction Roller Specification

- Features

- Low noise operation, durable, easy installation

- Surface Finish

- Polished / Rubber coated

- Power Source

- Not required or electric motor (when automated)

- Belt Type

- Compatible with flat or V-belts

- Thickness

- Roller wall thickness: 3 mm

- Material

- Mild steel or stainless steel with rubberized coating

- Type

- Friction Roller

- Structure

- Cylindrical roller with precision bearings

- Belt Conveyor

- Can be integrated

- Roller Conveyor

- Compatible

- Resistant Feature

- High resistance to abrasion and corrosion

- Load Capacity

- Up to 300 kg per roller

- Voltage

- Not required (mechanical operation)

- Power

- Manual or powered depending on system configuration

- Speed

- Variable, up to 120 m/min

- Usage & Applications

- Material handling, packaging, assembly lines, warehouses

- Axle Design

- Spring-loaded or fixed axle

- Noise Level

- Low noise operation

- Application Industry

- Logistics, Manufacturing, Warehousing, Distribution

- Mounting Type

- End/bearing mounted

- Roller Spacing

- Adjustable as per requirement

- Installation

- Easy to install and replace

- Length Range

- 300 mm to 1500 mm or as specified

- Operating Temperature

- -10°C to 80°C

- Customization

- Available for length, material, diameter, and finish

- Roller Diameter

- 50 mm, 60 mm, or custom sizes

About Friction Roller

Advanced Application and Versatile Features

Our Friction Rollers are designed for seamless integration into belt or roller conveyors, supporting both manual and powered systems. Engineered for flexibility, they cater to diverse commercial needs, such as packaging, warehousing, assembly lines, and logistics. With adjustable roller spacing and a load capacity of up to 300 kg per roller, these rollers boast high abrasion and corrosion resistance, low noise operation, and exceptional durability, ensuring reliable material handling across multiple environments. Installation and routine replacement are quick and simple for added convenience.

Sample Availability, Payments, and Shipping Information

Sample friction rollers are available upon request so you can evaluate their performance before placing bulk orders. Payment terms are flexible and designed for convenience. Products are professionally packaged to ensure they reach you in pristine condition. Freight charges are calculated based on order volume and destination, with items securely shipped across India and abroad. Whether ordered individually or in bulk, your rollers are protected and organized for straightforward handling upon delivery.

FAQs of Friction Roller:

Q: How can I customize the Friction Roller for my specific application?

A: You can specify the roller diameter, length, material, surface finish, and axle design during your order. We offer custom solutions tailored to your operational needs, ensuring an optimal fit for any system.Q: What industries benefit most from using these Friction Rollers?

A: These rollers are widely used in industries such as logistics, manufacturing, warehousing, packaging, and distribution, offering reliable and efficient material handling in various commercial settings.Q: When is it recommended to use the spring-loaded axle design?

A: Spring-loaded axles are ideal when frequent installation or roller replacement is necessary, as they allow for quick and tool-free changes, enhancing maintenance efficiency.Q: Where are these Friction Rollers manufactured and shipped from?

A: All friction rollers are manufactured in India, ensuring strict quality control. They are shipped nationwide and internationally, with freight charges calculated based on location and quantity.Q: What is the process for installing Friction Rollers?

A: Installation is straightforwardmount the rollers on the conveyor frame using standard end or bearing brackets. Adjust roller spacing as required, and replace as needed without specialized tools.Q: How do these rollers benefit conveyor systems?

A: Friction rollers reduce noise, withstand abrasion and corrosion, and offer adjustable speeds, significantly enhancing operational efficiency and longevity of conveyor systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Components Category

Flexible Conveyors

Minimum Order Quantity : 1 Meter

Load Capacity : 100 Kilograms (kg)

Structure : Roller

Material : MS/SS

Type : Incline and Decline Conveyor

Surface Finish : Crome

Self Aligning Carrying Idler

Load Capacity : Standard and customized options available, typically up to 3 tons per idler

Structure : Other, Heavy Duty Steel Frame with Rollers

Material : Mild Steel / Stainless Steel / Rubber Coated (Optional)

Type : Other, Self Aligning Carrying Idler

Surface Finish : Powder Coated / Painted / Galvanized

Tail Pulley

Minimum Order Quantity : 100 Pieces

Load Capacity : Up to 5000 kg Kilograms (kg)

Structure : Other, Heavy Duty Steel

Material : Mild Steel or Stainless Steel

Type : Other, Tail Pulley

Surface Finish : Painted / Powder Coated

HDPE Roller

Load Capacity : Up to 200 kg per roller

Structure : Other, Cylindrical, Troughing or Flat

Material : HighDensity Polyethylene (HDPE)

Type : Other, HDPE Conveyor Roller

Surface Finish : Smooth, Low Friction

|

KHODIYAR INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry